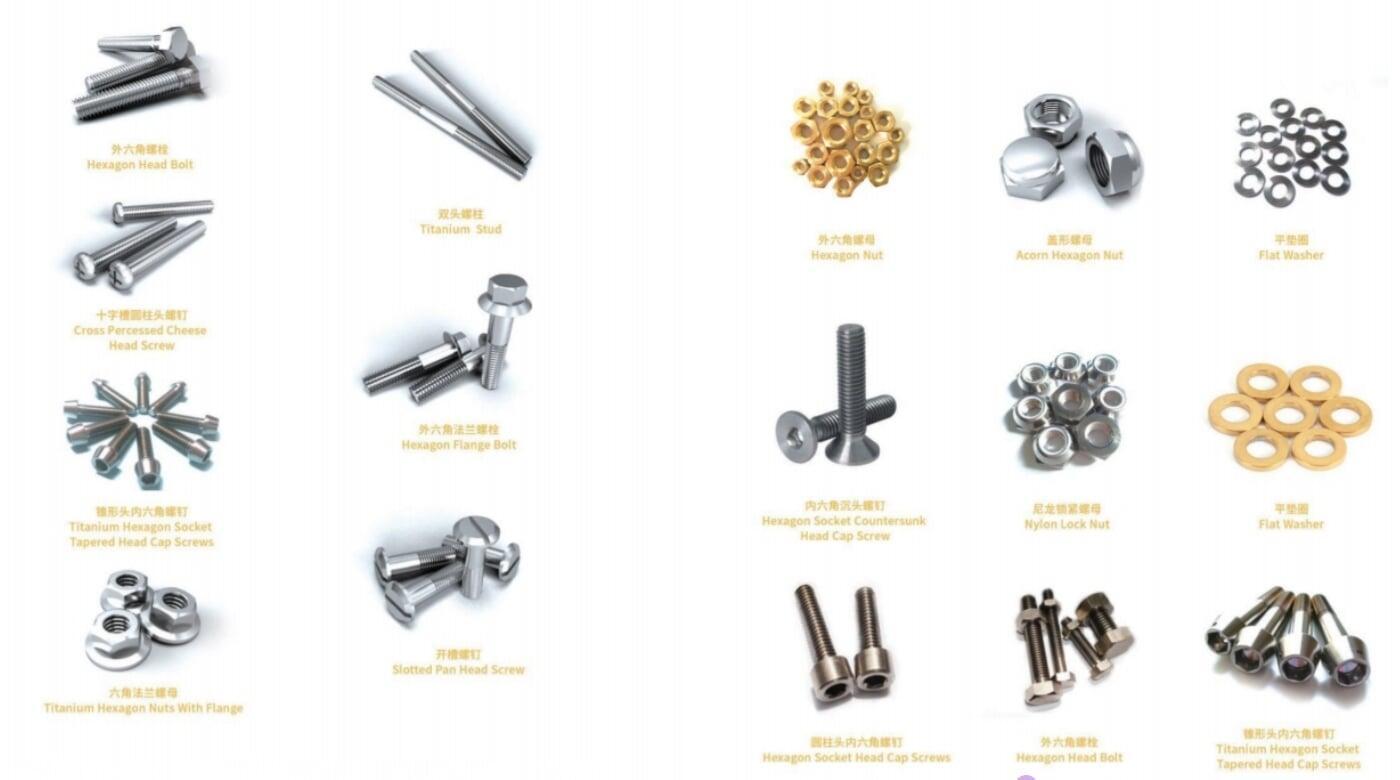

Titanium standard parts

GR1 Titanium standard parts

GR1: a kind of industrial pure titanium, suitable for occasions with high requirements for molding performance.

Features: Low density, high strength: Titanium standard parts have low density and high strength, which is an ideal material for lightweight design.

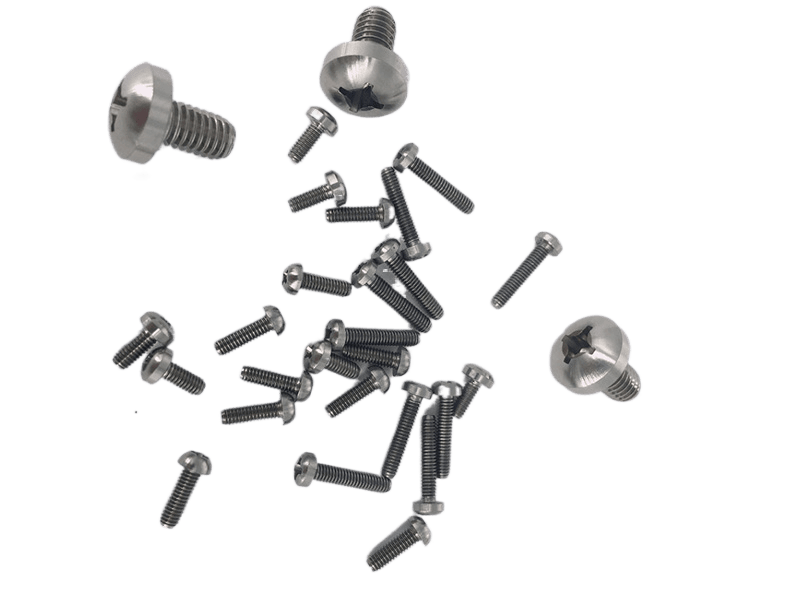

We are a manufacturer of titanium screws. We can customize them according to your needs,

and we can also provide standardized products. If you are interested in our products,

you can contact us and look forward to cooperation.

GR2 Titanium standard parts

Model GR2: Commonly used industrial pure titanium in industry, because of its corrosion resistance and comprehensive mechanical properties.

Features: Non-magnetic and non-toxic: suitable for medical, electronic and other fields that require non-magnetic and nontoxic.

We are a manufacturer of titanium screws.

We can customize them according to your needs,

and we can also provide standardized products.

If you are interested in our products,

you can contact us and look forward to cooperation.

GR3 Titanium standard parts

Model GR3: It can be used when the wear resistance and strength requirements are high.

Features: Good heat resistance, low temperature resistance: suitable for applications in high temperature and low temperature environments.

We are a manufacturer of titanium screws. We can customize them according to your needs,and we can also provide standardized products. If you are interested in our products, you can contact us and look forward to cooperation.

GR5 Titanium standard parts

GR5 Titanium standard parts

GR5 type: Stable performance for a long time in a variety of corrosive environments

Features: They are especially suitable for chemical, marine and other application scenarios that need to resist corrosion.

We are a manufacturer of titanium screws. We can customize them according to your needs,and we can also provide standardized products. If you are interested in our products, you can contact us and look forward to cooperation.

GR7 Titanium standard parts

GR7 Titanium standard parts

GR7 type: It has good biocompatibility and is suitable for biomedical fields such as medical implants

Features: Good compatibility with human tissues, reducing the risk of rejection and infection.

We are a manufacturer of titanium screws. We can customize them according to your needs,and we can also provide standardized products. If you are interested in our products, you can contact us and look forward to cooperation.

GR9 Titanium standard parts

GR9 Titanium standard parts

GR9 type: It has good machinability and can be molded and processed by various processing methods

Features: Widely used in aerospace, petrochemical, medical, automotive and other fields.

We are a manufacturer of titanium screws. We can customize them according to your needs,and we can also provide standardized products. If you are interested in our products, you can contact us and look forward to cooperation.We are a manufacturer of titanium screws. We can customize them according to your needs,

and we can also provide standardized products. If you are interested in our products,

you can contact us and look forward to cooperation.

Titanium standard parts are mainly made of titanium and titanium alloys such as GR1, GR2 and GR3. These materials impart excellent mechanical properties and corrosion resistance to titanium standard parts. Titanium standard parts are mainly divided into several categories, such as titanium screws, titanium bolts, titanium nuts, titanium screws, etc., and each category contains a variety of products with different specifications and shapes.

peculiarity

Low density and high strength: Titanium is only 55% dense than iron, but its strength is comparable to that of high-grade alloy steel. This makes the titanium standard parts lightweight and high-strength, and suitable for applications with strict requirements for weight and strength.

Excellent corrosion resistance: Titanium standard parts can maintain good stability in various corrosive media, especially in strong corrosive environments such as seawater and chloride.

Non-magnetic and non-toxic: titanium standard parts will not interfere with the magnetic field, and are harmless to the human body, suitable for medical, electronic and other special fields.

Good heat resistance and low temperature resistance: Titanium standard parts can maintain stable performance in high and low temperature environments, and are suitable for extreme working conditions.

Titanium standard parts are widely used in the following fields:

Aerospace: used in the manufacture and maintenance of aircraft, rockets and other aircraft, to meet the requirements of lightweight, high strength and corrosion resistance.

Chemical equipment: used for the connection and fastening of chemical equipment, to withstand the erosion of various corrosive media.

Medical devices: used in the manufacture of various medical devices, such as artificial joints, dental implants, etc., to meet the requirements of non-toxicity, corrosion resistance and biocompatibility.

Electronics industry: fasteners for the connection and fixing of electronic devices, such as mobile phones, computers and other products.

Dimensions & Standards

Titanium standard parts are available in a variety of sizes and specifications and can be customized according to customer needs. Common sizes include M4~M25×L, etc. The production and inspection of titanium standard parts follow the relevant international and domestic standards, such as GB/T, DINISO, etc., to ensure the stability of product quality and performance.